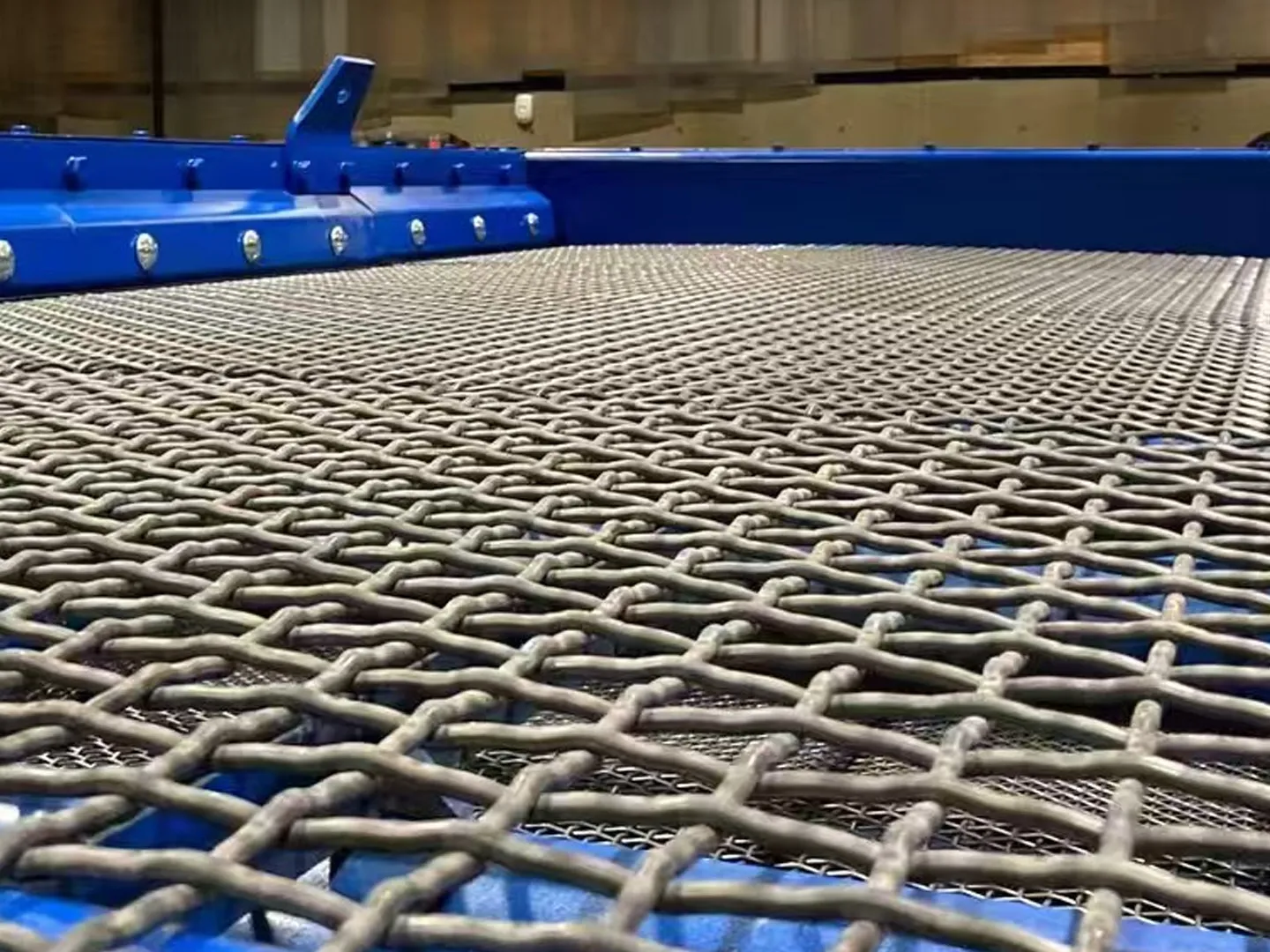

Industrial Woven Wire Mesh & Screening Media Manufacturer

Anpeng Wire Mesh is a family-owned industrial woven wire mesh and screening media manufacturer with 20+ years of experience serving mining and aggregate processing. We produce durable woven wire mesh, self-cleaning screens, and polyurethane screening solutions in our integrated 345,000 sq. ft. facility. By controlling every step—from wire drawing to final shipping—we deliver consistent quality, competitive cost, and shorter lead times for customers in 20+ countries.

Industrial Screening Media

Why Choose Us

FAQs

What's your advantages?

Scale & Capacity

345,000 sq ft facility with 35 production lines for rapid delivery.

Diverse Innovation

Cross-industry expertise drives continuous advancement in screen design and materials.

Standards Coverage

Supports both imperial and metric standards, with fast custom capability.

Stringent QC

ISO-certified. ±3% aperture tolerance (tighter than industry norm) ensures consistency.

Cost Efficiency

Comparable quality to global leaders with lower total cost.

How to choose screening media?

Selecting the right screening media is crucial for maximizing screening efficiency, durability, and cost-effectiveness. Focus on these key factors:

Material Properties

Consider size, abrasiveness, moisture, and stickiness.

Example: Abrasive materials require hardened steel or polyurethane; sticky materials benefit from self-cleaning screens.

Screening Objective

High Precision: Polyurethane screens are often ideal.

High Capacity: Robust metal screens (e.g., punch plates) are suitable for scalping.

Media Type & Application

Metal Screens: Best for heavy-duty, high-impact tasks (e.g., large aggregates).

Polyurethane Screens: Offer superior wear life and resist blinding for fine, abrasive, or corrosive materials.

Self-Cleaning Screens: Perfect for damp, sticky materials to prevent clogging.

Total Cost of Ownership

Evaluate longevity, maintenance, and productivity impact, not just initial price. Durable screens often provide a lower cost per ton.

Can I customized the products?

Yes, please address your specifications or needs, we could customize all products.

How long is delivery time?

Your order can be shipped out within 7-15 days.

Do you provide samples?

We provide free samples, samples could be shipped out with your existing order or you could pay for shipping and samples will be shipped to you immediately.

Is our screens easy to install?

Yes, our screens are easy to install, takes only one to two workers to install.

How can your products offer both high durability and cost-effectiveness?

Our products achieve this balance through a combination of scale and expertise. Our efficient, large-scale manufacturing keeps initial costs competitive, while our engineered designs—proven in demanding markets—significantly extend product life, reducing your long-term replacement and downtime costs. This delivers greater overall value.

Contact Us

Fill out the form — our engineers will reply within 24 hours with a tailored proposal.