The screening mesh exists in both crushing equipment and screening equipment, and is an essential part of the crushing and screening process.

When selecting the vibrating screen mesh, we usually choose the mesh that can meet our screening needs based on the customer's material type and particle size. What are the differences in performance, material and application?

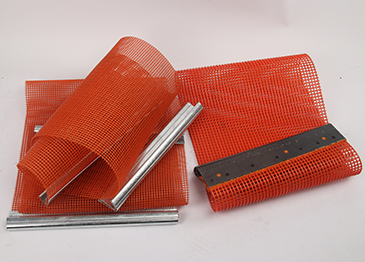

A metal mesh structure element used for screening and filtering, and can be made into various rigid screening and filtering devices.

Application: Industrial wire screens provided by industrial screen manufacturer are widely used in various industries for screening, filtering, dewatering and desilting operations.

Features: High strength, stiffness and load-bearing capacity.

Rectangular hole screen mesh, diamond anti-blocking screen mesh, wave anti-blocking screen mesh.

Application

Rectangular hole screen mesh: generally, if the stone particles are relatively regular and dry, and there are not too many flaky materials, the rectangular hole screen mesh can be selected;

Diamond anti-blocking screen mesh: If the stone particle size distribution is demanding and there are more flaky materials, the diamond anti-blocking industrial screen mesh should be selected first, such as screening of stones in asphalt surface of highways;

Wave anti-blocking screen mesh: For intermediate screening, such as adding screening between coarse screening and fine screening, wave-blocking hole screen mesh is recommended. The advantage is that the screening efficiency is high and it is suitable for the screening of materials with more dust, such as tailings.

Features

Expanding the planar two-dimensional fixed hole to a three-dimensional variable diamond-shaped screen hole, using the secondary vibration generated by adjacent screen bars during random vibration to establish effective vibration difference, and achieve the continuous change of the screen hole in the screening process of industrial screen mesh.

There are no fixed critical particle stones, and the specific method is to set a relatively movable screen bar between two static screen bars. The movable screen bar can bounce the stone material during the stuck period or pass it through the screen.

According to the characteristics of the stones, the relative elastic force and vibration amplitude of the static and dynamic screen bars are adjusted correspondingly, so that the screen mesh is in the best screening state.

The screening efficiency can be improved by about 30% compared to the fixed-hole screen mesh, and the self-cleaning function of the screen mesh is basically achieved, greatly reducing the blockage of the screen hole.

Meaning

Polyurethane, also known as polyurethane elastomer or TPU, is a general term for macromolecular compounds whose main chains contain repeating carbamate groups (NHCOO).

Application

Polyurethane screen mesh belongs to mining equipment and is used in mining and quarrying, combined with vibrating screens and other mining equipment.

Features

The material has a beautiful appearance, and bright colour, is lightweight, has high mechanical strength, heat insulation, sound insulation, corrosion resistance, excellent weather resistance, no need for secondary decoration, and various colours.

Good wear resistance, long service life. Its wear resistance is 3-5 times that of steel screen plates, and more than 5 times that of ordinary rubber screen plates.

Small maintenance workload. Polyurethane screen mesh is not easily damaged and has a long service life, therefore, maintenance and replacement time can be greatly reduced, and production loss can be reduced.

Low total cost. Although the same size polyurethane screen mesh has a higher one-time investment than stainless steel screen plates, the service life of polyurethane screen mesh is 3-5 times that of stainless steel screen plates, and the maintenance and replacement times are few. Therefore, the total cost is not high and it is more economical.

Good moisture resistance. It can work under the condition of water as the medium, and the friction coefficient between polyurethane and material is reduced under the condition of water, oil and other media, which is more conducive to screening, improves the screening efficiency, and can avoid the adhesion of humid particles, which has a high service life.

Corrosion resistance, non-flammable, non-toxic and tasteless.

Due to the reasonable design of the screen hole and the unique manufacturing process of the screen plate, the maximum size of particle will not block the screen hole.

Good vibration absorption and strong sound absorption ability can reduce noise and make the material on the screen not easy to break during vibration.

Due to the characteristic of secondary vibration of polyurethane, polyurethane screen mesh has a self-cleaning function, so the screening efficiency is high.

Energy-saving and consumption-reducing. Because the specific gravity of polyurethane is small, the weight of the screen is much lighter than that of the same size steel screen, which reduces the load of the screening machine, saves electricity consumption, and prolongs the service life of the screening machine.

You may also be interested in wire mesh wholesale offered by screening mesh suppliers Anpeng: