The ore screen is an element with a metal mesh structure, which can be used for sifting and filtration. It is used in sieving, filtration, dehydrating, desliming and other operations with high strength, stiffness, and load-carrying capacity, and can also be made into various shapes of rigid screening filtration devices. It is easy to leak, wear-resistant and corrosion-resistant. The mesh section is trapezoidal, and the upper gap is narrow and the lower wide. It is widely used in mining, coal, petroleum, fertilizer, grain, salt, environmental protection and other industries.

What is ore screen? Presumably, such a professional term has rarely been heard of. In fact, to be frank, it is an element similar to the metal structure, which is mainly used for filtration, sifting, dehydrating, desliming, and other operations. The shape is mostly trapezoidal, narrow on the top and wide on the bottom. So what is the classification of the ore screen? And what are their respective features? Certainly, different types of ore screens have different features, materials and functions. If you have this need, you may wish to follow me to understand the classification of the ore screen and related knowledge.

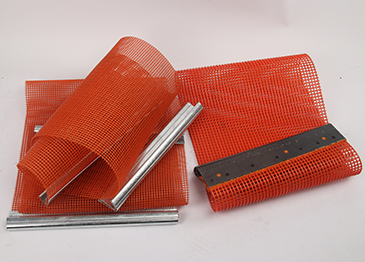

The ore screen is a newly-developed product of the China wire mesh screen industry. It is an element of metal mesh structure used for sifting and filtration. The ore screens are classified into polyurethane screens, manganese steel ore screens and stainless steel ore screens.

The ore screen has a high screen net rate with the function of wear resistance, corrosion resistance, anti-skidding, vibration resistance, strong elasticity, toughness, and non-convergence. The mesh section is trapezoidal. The gap is narrow on top and wide on the bottom. It is made of stainless steel square wire mesh cold rolled sieve strip, support strip using automated mine screen production equipment welded, sieve seam uniform, stable welding quality, high open rate, long service life, high strength, stiffness, and bearing capacity, can be made into a variety of shapes of steel screening filter device.

Stainless steel welded ore screens, screen baskets, vibrating screens, strip sieves, cylindrical meshes, curved screen heterosexual screens, high-strength screens, polyester ore screens, etc.

Stainless steel welded ore screen, strip sieve piece, sieve plate sieve basket, welded vibration screen, cylindrical meshes, curved sieve.

The production and manufacturing method of the ore screen: one is the welded strip sieve, and the other is the custom woven wire mesh. Anpeng after several years of hard work, ore screen, ore sieve and ore screen factory have already had advanced production equipment with strong technical force, scientific process flow, perfect quality testing system, and use high-quality raw materials, perform strict quality control for the customers' unanimous praise. The manganese steel ore screen adopts the embedded (Mn65-Q) weaving method, the longitude and weft overlap points are not prominent, the surface is flat, and the force is uniform. The hardness is HB180-230, which has good plasticity and toughness. When subjected to strong impact and friction, the surface is strongly hardened due to plastic deformation, and the surface hardness value can be increased to be more than HRC60, so as to obtain high wear resistance, while the interior still maintains high plasticity and toughness. When the old surface wears, the new surface will form a wear-resistant layer, so the life can reach 3-5 times that of ordinary ore screens.

You may also be interested in Anpeng's vibrating screen mesh, heavy-duty wire mesh screen, mining screens, etc. Welcome to contact us.