The polyurethane screen mesh is a common type of screen mesh. With the continuous development of the national screen industry, the application of polyurethane screen mesh is becoming more and more widespread. So, what are the characteristics of polyurethane screen mesh? How is it different from traditional screen mesh? Let's take a look today!

Conventional mining precision screen mesh generally uses metal weaving or nylon precision screen mesh. Due to poor wear resistance and corrosion resistance, metal weaving screen mesh is often replaced, with high labor intensity and cost. Metal screen mesh has poor elasticity and fixed aperture size, leading to easy blockage of holes during screening, affecting screening power, and generating high noise during operation.

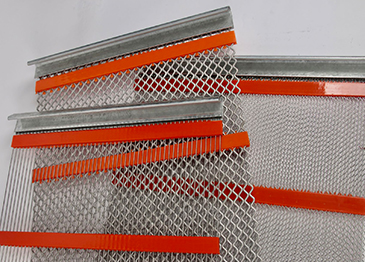

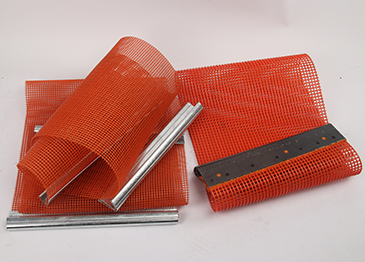

Nylon precision screen mesh is made of thermoplastic nylon injection molding. Due to the limitations of thermoplastic molecular injection molding technology, it is impossible to make a large-sized single mesh. In the process of use, only small-sized screen mesh can be used and connected together. Due to large joint gaps and screening defects, the opening rate of screening is low, usually less than 10%, and the screening efficiency is also low. Polyurethane screen mesh makes up for the shortcomings of traditional screen mesh. It has high standards, good elasticity, wear resistance, light weight, long service life, low noise, and no joints during use. It has been widely recognized by users and is widely used in industries such as mining, coal washing, coal, iron ore, metallurgy, and water conservancy.

After selecting the appropriate polyurethane screen mesh, it should be used reasonably to maximize its performance and extend its service life. However, many users often overlook this point in the process of using polyurethane net. For example, the tightened screen mesh is easy to loosen under the impact of large materials during use, and the fastening bolts need to be rotated regularly. At the same time, there is an inlet design, which is excellent to ensure that the conveyed material is not perpendicular to the screen surface. The material should be tilted along the logistics direction in feed direction, and the feed height should not exceed 400mm to avoid excessive impact and damage to the screen mesh.

If the raw materials of polyurethane screen mesh are the same, the main factor affecting its quality is processing technology. Before casting, polyurethane screen mesh must be processed using appropriate molds and frames. Corresponding treatment should be carried out on the temperature and oil pollution on the frame surface. Improper treatment of surface oil pollution will affect bonding, and the frame and polyurethane screen mesh are easy to peel off. Improper temperature control during injection molding will cause bubble formation in the polyurethane screen mesh, affecting its service life.