Nowadays, the self-cleaning screen is becoming more and more subdivided, which can be used not only to sift grain, but also to sift many other things. So what areas can the self-cleaning networks be applied in? What are its features? Please read on:

Application area: For sieving and filtration under the condition of acid and alkali environments, petroleum industry for mud mesh, chemical fiber industry, as sieve filter, electroplating industry for pickling net.

Acid resistance, alkali resistance, and rust resistance are good; Large span bridge;

Self cleaning screen mesh is high strength, tensile strength, toughness;

Resistant to high-temperature oxidation, 304 stainless steel screen nominal resistance temperature of 800 degrees Celsius, 310S stainless steel screen nominal resistance temperature up to 1150 degrees Celsius;

Normal temperature processing, that is, easy plastic processing, so that the use of stainless steel screens can be used to diversify;

High finish, no surface treatment required, easy and simple maintenance.

The self-cleaning network is widely used for sifting, filtration, and protective decoration, and the scope of its application covers the mining industry, petroleum, chemical, food, machinery manufacturing, building decoration, electronics, aerospace, and so on.

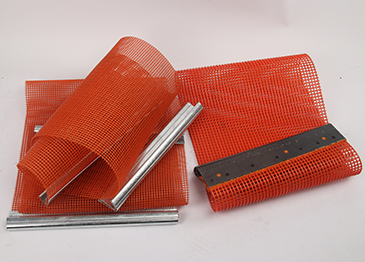

The self-cleaning network refers to the regular arrangement of mesh products produced by and processed from stainless steel materials such as stainless steel wires or plates. The wavy screen is also a kind of self-cleaning network, the wave type of vibrating screen is also known as the wave type mud vibrating screen, the mesh surface is uniquely wavy, and the method of installation can be a wedge-shaped pressing device with a hook edge or a steel frame mesh. The effective filtration area of the wave screen can reach 125% to 150% of the same size as the flat screen' The processing capacity is greatly improved. Our factory can manufacture a variety of specifications and sizes of wave screens according to the needs of different customers. Wave-shaped vibrating screen, also known as wave-type mud vibrating screen, has a unique wavy screen surface. The installation method can be a hook edge or a wedge-shaped pressing device of the steel frame mesh. The effective filtration area of the wave screen can reach 125% to 150% of the same size of the flat screen. Thus, the processing capacity is greatly improved. Our wire mesh factory can manufacture a variety of specifications and sizes of wave screens according to the needs of different customers.